2016-11-11 Rongda test 1375 times

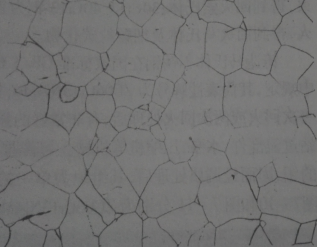

Detection Purpose: Test the metallographic structure of stainless steel

Detection range: Oil pipeline, boiler, liquefied gas tank and other pressure vessels, metal and other products

A kind of high alloy steel that can resist corrosion and has high stability in air or chemical corrosion medium. Stainless steel has good corrosion resistance and beautiful surface. It does not need to go through surface treatment such as plating color, but plays the inherent surface performance of stainless steel and is used in many aspects. From the perspective of metallography, because stainless steel contains high chromium, chromium forms a very thin chromium film on the surface, which separates the oxygen invading the steel and thus plays a role of corrosion resistance. Classification by metallographic structure: ①. Austenitic stainless steel (200 series, 300 Series) ②. Ferritic stainless steel (430, 446, etc.) ③. Martensitic stainless steel (410 system, 420 system and 440C system) ④. Duplex stainless steel (Cr18, cr23, Cr22 and Cr25) ⑤ precipitation hardening stainless steel

Last article: NO!

Next article: NO!