Metallographic analysis is one of the important means in the experimental research of metal materials. Based on the quantitative metallographic principle, the three-dimensional spatial morphology of the alloy structure is determined by the measurement and calculation of the metallographic microstructure of the grinding surface or film of the two-dimensional metallographic sample, so as to establish the quantitative relationship among the composition, structure and performance of the alloy. The application of image processing system in metallographic analysis has the advantages of high precision and high speed, which can greatly improve the work efficiency. Computer quantitative metallographic analysis is gradually becoming a powerful tool for people to analyze and study all kinds of materials, to establish the quantitative relationship between the microstructure and various properties of materials, and to study the transformation dynamics of materials. The computer image analysis system can easily measure the area percentage, average size, average distance, length width ratio and other parameters of the feature, and then determine the three-dimensional space shape, quantity, size and distribution of the feature according to these parameters, and establish the internal relationship with the mechanical properties of the material, so as to provide reliable materials for more scientific evaluation and rational use Data.

Non metallic inclusion detecti...

非金属夹杂(non一metalli。inelusion)金属中含有的非成分和性能所要求的非金属相。非金...

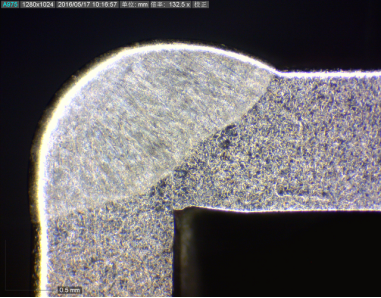

Macro metallographic examinati...

宏观金相:用肉眼或低倍放大镜(放大倍数一般小于50)检查试样,试样表面可处理或不处理...

Forging streamline inspection

锻造流线也称流纹,在锻造时,金属的脆性杂质被打碎,顺着金属主要伸长方向呈碎粒状或...

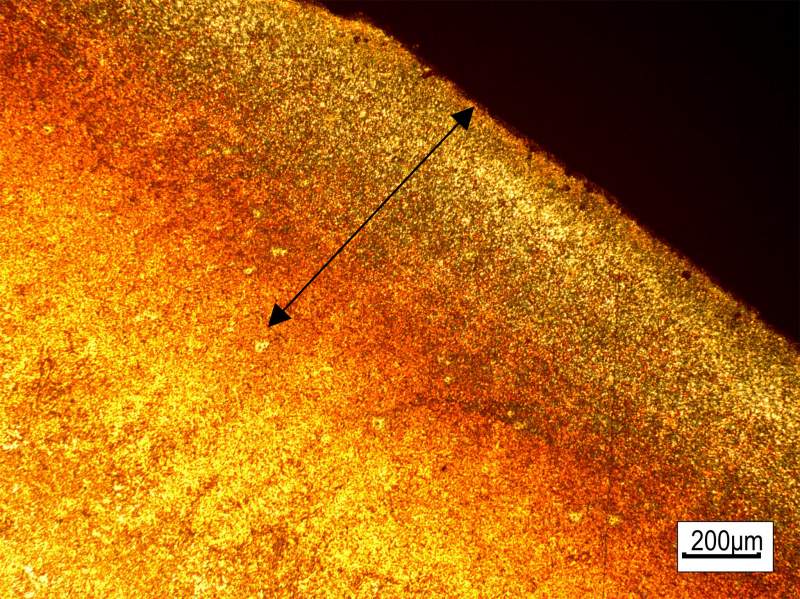

Carburizing layer depth detect...

渗碳层就是渗碳件中含碳量高于原材料的表层。渗碳是指使碳原子渗入到钢表面层的过程。...