corrosion test![]()

Valve detection![]()

Metallographic analysis![]()

component analysis![]()

Mechanical test![]()

failure analysis![]()

Nondestructive flaw detection![]()

2017-04-12 Rongda test 1365 times

Detection Purpose: Inspect the material's ability to resist stress - directed hydrogen cracking

Detection range: Valves, flanges, oil pipelines, boilers, liquefied gas tanks and other pressure vessels, metal and o

SOHIC test:

The stress - guided hydrogen cracking test is to evaluate the cracking sensitivity of carbon steel in hydrogen sulfide aqueous solution. SOHIC experiment performed according to NACE TM0103 standard is a more rigorous anti-corrosion evaluation method than SSC experiment.

When carbon steel plates used in welded pressure vessels work in a wet hydrogen sulfide environment, they may suffer one or more forms of environmental cracking.

These cracks include:

(1) high-hardness weld and heat-affected zone sulfide stress corrosion cracking (SSC);

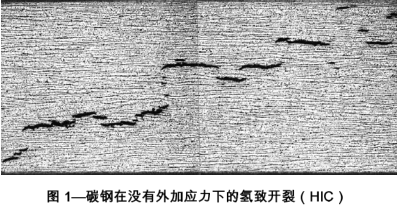

(2) hydrogen cracking of matrix metal (HIC);

(3) stress - guided hydrogen cracking (SOHIC).

Stress - directed hydrogen cracking

Last article: NO!