corrosion test![]()

Valve detection![]()

Metallographic analysis![]()

component analysis![]()

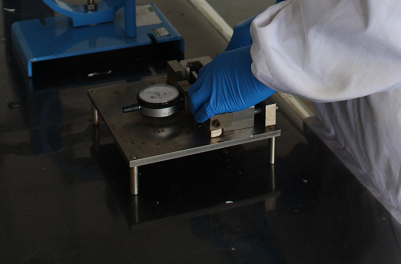

Mechanical test![]()

failure analysis![]()

Nondestructive flaw detection![]()

2016-11-11 Rongda test 1229 times

Detection Purpose: Testing the environmental resistance of materials used in oil and gas environment to hydrogen sulfid

Detection range: Oil pipeline, boiler, liquefied gas tank and other pressure vessels, metal and other products

Under the general title of "materials for use in H2S containing environments in oil and gas production", ANSI / NACE mr0175 / ISO 15156 includes the following parts: &Mdash; & mdash; Part I: General criteria for selection of cracking resistant materials &Mdash; & mdash; Part II: use of cracking resistant carbon steel, low alloy steel, and cast iron &The third part: CRAs and other alloys. NACE Mr 0175 standard includes test items: corrosion cracking mechanism possibly caused by H2S, including sulfide stress corrosion cracking (SSC), stress corrosion cracking (SCC), hydrogen induced cracking (HIC), stepped cracking (SWC), stress guided hydrogen induced cracking (SOHIC), soft zone cracking (szc) and couple induced hydrogen stress cracking.